honeycomb facade panels

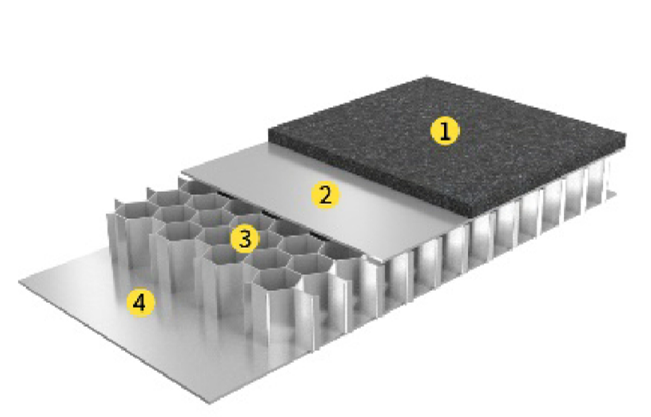

At the cutting edge of facade tech, the ultralight honeycomb panel consists of a hexagonal aluminium backpanel supporting a light layer of concrete, stone, ceramic or metal, upto 3mm thin.

This allows complex profiles such as L-mounts and U-mounts to be prefabricated. It also allows large panels to be installed easily and rapidly.

With reduced material and installation costs, honeycomb panels enable unparalleled cost savings for even the most intricate facades.

Cutting-edge material technology

- Facade material (concrete, ceramic, stone, metal, etc)

- Upper aluminium surface

- Inner honeycomb structure

- Lower aluminium surface

prefabricated mounts

Ultralight panels allow prefabrication of a variety of mounts.

The unique engineering behind honeycomb technology allows for seamless corners, ensuring elements with multiple panels maintain the look of a solid block.

The most common form-factors are U-mounts and L-mounts, but custom mounts can be fabricated to your needs.

versatile material choices

Honeycomb panels support a wide range of materials.

You can have your pick of material: concrete, natural stone, ceramics, metal and composites are all possible. You can even use the honeycomb without addition material to expose a gleaming alumnium facade.

Whichever material you use, honeycomb enables you to mount thinner panels than any alternative.

downloads

technical specifications

Below you will find the specifications for our aluminium honeycomb facade panels. The surface material of choice (concrete, ceramics, stone, metal, etc) would have seperate specifications not included in the numbers below. These can be provided seperately.

| Items | w/ Thermoplastic Films | w/ Modified Epoxy Adhesive |

|---|---|---|

| Width | Upto 2000mm | |

| Length | Upto 6000mm | |

| Overall Thickness | 5mm to 500mm | |

| Aluminium Sheet Thickness | 0.5mm to 2.0mm | |

| Aluminium Alloy | 3003 / 5052 | |

| Flatwise Tensile Strength | 1.4Mpa | 2.0Mpa |

| Flatwise Compressive Strength | 2.0Mpa | 2.0Mpa |

| Flatwise Shear Strength | 0.5Mpa | 0.8Mpa |

| Drum Peeling Strength | 50N.mm/mm | 60N.mm/mm |

| Flexural Strength | 60Mpa | 60Mpa |

| Temperature Resistence | Up to 120°C | Up to 80°C |

Fire resistence: A2-s1-d0

get in touch

Write our international sales office at info@graccofacades.com or get in touch with our sales lead:

- Javier Masfarre

- javier@graccofacades.com

- +34 629 737236

- Calle Roses 13.

- 08850 Gavà (Barcelona)

- Spain